The under mentioned two techniques are usually used for materials planning:

1. Bill of Materials Technique, and

2. Past consumption Analysis Technique.

Bill of Materials Technique

A bill of materials indicates the name, part, and usage of each component and the sub- assembly in which it is to be used. Each product has a bill of materials since each of the products has its own equipments dependent on its design and according to the engineering designs and the components consisting of standard parts need for particular product to be manufacture. If a chair is to be prepared it can be split into (i) legs (ii) arms, (iii) seat, (iv) back rest. Each of the parts of the chair will have separate specifications and naturally each may have its own manufacturing design.

According to the specifications and design, the bill of materials will be drawn on such composite information for the product – the chair in this case. In a bill of materials for a product, the components required may be procured according to the specifications. When any of the units of the organization receives a work order or production programme is finalized, the concerned foreman prepares a list of all the materials required for the execution of the order or manufacturing of the product as per production programme. The list of materials so prepared is known as a bill of Materials which includes all the details as regards to quality, quantity, code number, and other necessary specifications, etc.

Once the production programme is finalized, each product is exploded (split) into its basic requirements with the help of it’s of materials. The number required per item is multiplied by the number to be produced in order to arrive at the total requirement. The total requirements are further adjusted for various losses. Rejections should also be provided for. Every care should make for them. Provisions for stock and lead time consumption should be made. Taking all these provisions into consideration the bill for materials should be drawn for each component and then through multiplication process total requirement should be obtained.

The bill of materials – known as BOM – is the simplest technique of materials planning .BOM with required lead -time and necessary contingency provisions is drawn which eventually turns into indents for procurement. it also acts as a guide to delivery and inventory requirement. BOM, therefore, helps in keeping watch over the delivery of matching equipments, spare part, and components and also over materials directly going into production. It enables the evaluation of the progress of the project undertaken and ensures the flow of need materials. Such an avoidance of capital blockage saves and diverts the working capital and reduces the inventory carrying cost to a larger extent.

Explosion of Bill of materials

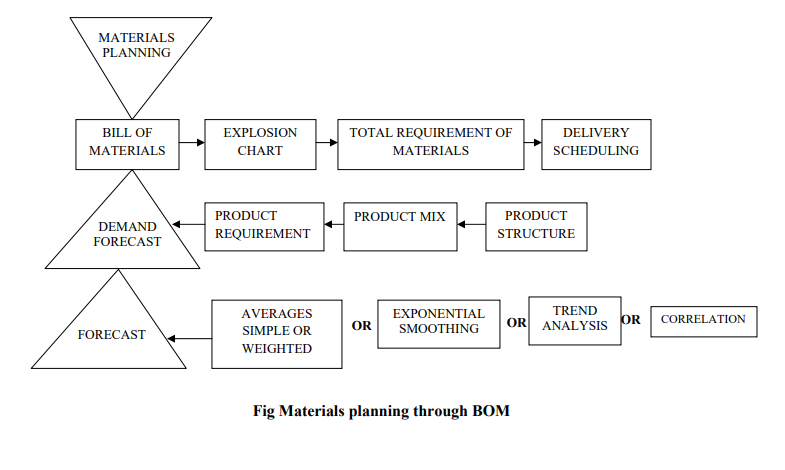

Explosion of bill of materials refers to splitting of the requirements for the product to be manufactured into its basic components; then by multiplication process we get the total equipments. This is very effectively done with the help of “demand forecasts”. As we have seen earlier, the very basis for material planning is the forecast of demand for the end products. For calculation of equipments for various materials, explosion charts, are conveniently used by the materials department. An explosion chart is a series of bills of materials grouped together by combing the requirements for a particular end – product or group of end – products. The above discussion may best be explained with help of the following chart;

Period and Suitability of BOM Technique

Bill of materials technique is ideally suited to engineering industries – both heavy and light since her large numbers of components are required for manufacturing or assembling and end-product which certainly required from various sources, which, as we have seen, is a convenient method of knowing the total requirements for an end product. There may be controversy so far as the period is concerned. It may vary from a month to a year depending upon the reliability of information and forecasts made. A forecast tends to become less reliable as the period goes on increasing.

Forecasts amply prove that they are reliable only to the extent to which the information and data are reliable. If prejudices and personal pride has not crept in and the fed data are nearly absolute, unbiased, and are based on sound judgment, then the forecasts may serve the purpose well and period may even exceed one year. But seldom had these conditions adequately fulfilled. It is because of this reason that ideal period for materials planning are advocated to be of three months. Planning on a quarterly basis is also safe in the present state of Kenyan economy in which inflationary pressure is upsetting all calculations and market conditions are far from satisfactory from both demand and supply points of view.

Owing to error in forecasting or change in the market conditions and the national or state policy the materials (either all or some of them) may either be in short supply or in excess. This surely would upset the plans, programmes and schedules. A materials planning done on a quarterly basis may rectify the errors, apply the correctives and bring the operation on the right track which in case of annual (or more) planning is rather difficult, if not altogether impossible.

Past Consumption Analysis Technique

Where materials are consumed on continuous basis, the technique of past consumption analysis for materials planning is conveniently used by the organization. According to this technique, future projection is made on the basis of the past consumption data, which is analyzed taking into account the past as well as future production plans. Statistical tools like mean, median, mode and standard deviation are used in analyzing the past consumption, projecting the future and tackling mild as well as wild fluctuations in consumption.

This technique can be successfully used in process industries. This technique can be fruitfully used for materials being used on continuous basis for which no straightforward norms of consumption can be easily worked out in the organization, and also for those materials which are either used directly or indirectly in the production process.